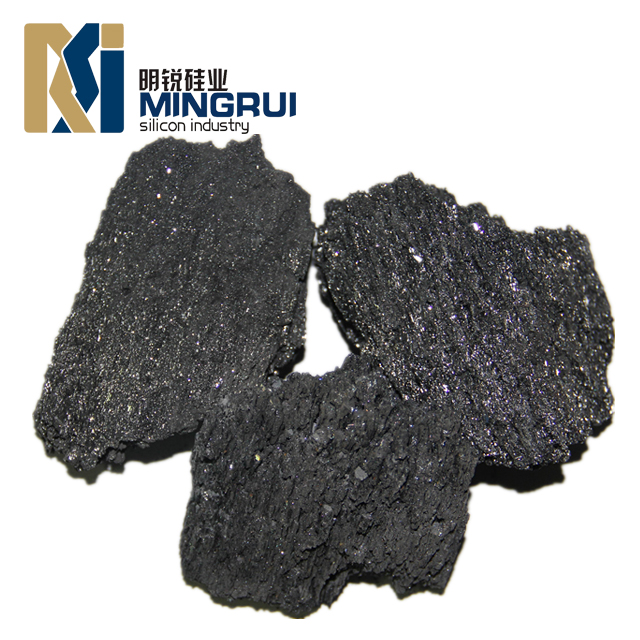

Silicon Carbide

Description

Silicon carbide (SiC) is made from quartz sand and petroleum coke( or coal tar), wood chips as raw material through high temperature smelting in electric resistance furnace.

Applications

1.Metallurgical deoxidizer

2.High temperature resistant materials

3.As abrasive, abrasive tools can be used to such as grinding wheels, whetstones, grinding head, sand tile etc

Advantages

1.Corrosion resistance, high strength, high hardness,

2.Good wear-resisting performance,resist to shock

3.Stable chemical performance, high thermal conductivity, high resistant temperature

Specification

Chemical Composition(%) | |||

SiC | F.C | Fe2O3 | |

>= | <= <= | ||

SiC98.5 | 98.5 | 0.20 | 0.60 |

SiC98 | 98 | 0.30 | 0.80 |

SiC97 | 97 | 0.30 | 1.00 |

SiC95 | 95 | 0.40 | 1.00 |

SiC90 | 90 | 0.60 | 1.20 |

SiC70 | 70 | 3 | |

SiC65 | 65 | 5 | |

SiC60 | 60 | 10 | |

55 | 10 | ||

SiC50 | 50 | 10 | |

Size: 0-10mm, 1-10mm or as per customers' requirement

Packing:1mt/big bag or as per customers' requirement

Remark: specification and size can be optimized by per customer' requirement

Japanese

Japanese Korean

Korean German

German French

French Russian

Russian Italian

Italian Spanish

Spanish Portuguese

Portuguese