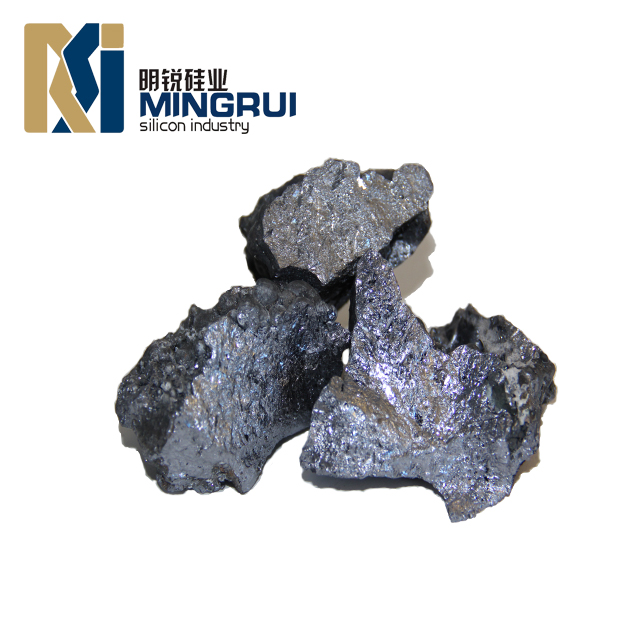

off grade silicon factory

Description

The silicon off-grade is a by-product from production of silicon metal of ≥99% purity. To ensure the quality of the silicon metal, top portion of the melt is separated when draining from the electric-arc furnace. The less pure portion of silicon metal typically contains higher contents of iron, aluminum, calcium and other slag. With the employment of density separation machines, different grades of off-grade silicon are segregated efficiently.

Applications

Off-grade material is much cheaper than ≥99% purity silicon metal, and has many industrial applications. For example, It is

1. Used as de-oxidizing agent in steel production to reduce oxygen levels in the melt via reaction such as

Si + 2 O (in liquid Fe) ––> SiO2

(SiO2 is formed as a solid dispersed in molten Fe, and subsequently floats to the surface of the melt. It is

removed by either skimming or by draining molten iron from the bottom);

2. Use as de-oxidizing agent in the production of magnesium, chromium and other metals via the same

mechanism;

3. Used in the production of lower grade of Si3N4 in a cost effective manner, the material is suitable for

refractory applications such as refractory bricks and other high-temperature applications;

4. An economical feedstock in the manufacture of silica sol or colloidal silica;

5. A low cost feedstock in the manufacture of organosilyl derivatives and silicone products.

Specification

Off grade Silicon | |||||

Type | Si | Al | S | P | C |

≥ | ≤ ≤ ≤ ≤ | ||||

Off grade Silicon 80 | 80 | 3 | 0.1 | 0.05 | 3.5 |

Off grade Silicon 85 | 85 | 3 | 0.1 | 0.05 | 3.5 |

Off grade Silicon 90 | 90 | 1.5 | 0.1 | 0.05 | 2.5 |

Off grade Silicon 93 | 93 | 1.5 | 0.1 | 0.05 | 2.5 |

Size: 10-60 mm, 1-3mm, 0-3mm or as requirements

Packing:1 MT per big Bag

Remark:Chemical composition and size can be optimized by the customers' requirements.

Japanese

Japanese Korean

Korean German

German French

French Russian

Russian Italian

Italian Spanish

Spanish Portuguese

Portuguese